Safety features for all Zinger horizontal media mills include a high pressure chamber shutdown which shuts down all operations if chamber is over pressure.

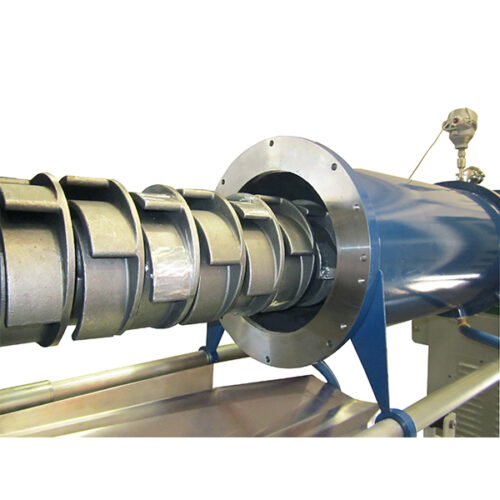

The MorehouseCowles Zinger™ horizontal media mill is completely sealed, self-contained grinding and dispersion mill produces fine and ultra-fine dispersions. The Zinger uses an exclusive rotor and vessel design to aggressively move media through the slurry and has proven to reduce particle size in significantly less time than the conventional disc mill design. This horizontal design requires less energy and allows the use of smaller media. Low to extremely high viscosity slurries are easily and efficiently processed using its unique rotor and chamber design.

How it Works

A prepared pre-mixed liquid/solid slurry is continuously pumped into a pressure-sealed horizontal chamber. The chamber contains grinding media and several shaft-mounted rotors. Each rotor is fitted with specially designed vanes. Media is accelerated at high velocity through the slurry toward the chamber wall, impacting, shearing, and reducing the size of the solid slurry particles. The chamber wall has several specifically-shaped projections reducing media acceleration, causing the media to return to the center and be accelerated over and over again. This prevents hydraulic packing, and typically develops finished micron to submicron dispersions in a single pass.

Grinding Media

The size and type of grinding media are the two most important factors in the quality and quantity of the product processed in a small media mill. There are numerous types and sizes of media available, consult our media experts for proper requirements. It is the combination of the media and the product that ultimately determines how well your mill performs.

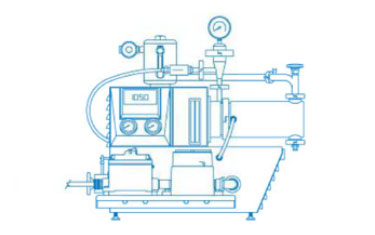

Laboratory Mills

For formulation development or small scale production batches, MorehouseCowles offers scaled down versions of our standard Zinger horizontal media mill, ideal for a laboratory setting.

Preventative Maintenance

For optimal performance, it is important to keep up with the preventative maintenance schedule. Recommended parts for Zinger horizontal mills include:

- Double Mechanical Seal

- Rotors/Discs

- Spring pin

- Belt

- Screen (various gap sizes available)

- Bearings for main shaft

- Viton O-ring Kit

- Gasket Kit

Customization

Our innovative engineering support teams are available to closely collaborate with customers to develop and design custom equipment and technology. Contact us to learn more.

Request a Quote

For pricing on MorehouseCowles equipment, complete our request for quote form today.