Safety features for all pressurized vertical media mills include a high pressure chamber shutdown which shuts down all operations if chamber is over pressure.

Our vertical media mill is a workhorse for continuous wet milling of aqueous and solvent slurries in a variety of viscosities. Its simple, reliable and easy to maintain design efficiently and uniformly mills product to the required particle or agglomerate size. The smaller and more uniform particle sizes produced by the vertical media mill enables smoother product consistency for better quality, enhanced performance and longer shelf life.

Our Offering

Sealed, Non-Pressurized Mills

MorehouseCowles non-pressurized mills are designed for small media to give you the best of both worlds – a simple, low maintenance design with a modest cost-per-unit for most applications.

Pressurized Mills: Single-Vessel

MorehouseCowles single-vessel pressurized mills are the most advanced and versatile mills designed for small media. They are ideal for difficult, high-viscosity material processing applications.

Safety Features

How it Works

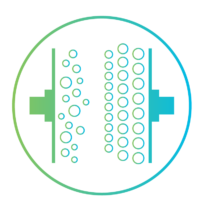

The cylindrical chamber of each MorehouseCowles mill is charged with media (grinding beads). Product enters the chamber at the bottom of the vessel and as it rises through the chamber the motion of the disks and grinding media produces impact and shear forces that deagglomerate particles, then it exits through the screen at the top. The particle size of the processed product is dependent on the size and type of media in conjunction with the flow rate. Particle size distribution of less than 1 μm are standard milling requirements. For maximum milling efficiency and consistency, the product should be pre-dispersed with a high-speed dissolver system before media milling.

Grinding Media

The size and type of grinding media are the two most important factors in the quality and quantity of the product processed in a small media mill. There are numerous types and sizes of media available, consult our media experts for proper requirements. It is the combination of the media and the product that ultimately determines how well your mill performs.

Customization

Our innovative engineering support teams are available to closely collaborate with customers to develop and design custom equipment and technology. Contact us to learn more.

Preventative Maintenance

For optimal performance, it is important to keep up with the preventative maintenance schedule. Recommended parts for vertical media mills include:

- Packing for stuffing box

- Rotors/Discs

- Spring pin

- Belt

- Screen (various gap sizes available)

- Bearings for main shaft

Request a Quote

For pricing on MorehouseCowles equipment, complete our request for quote form today.